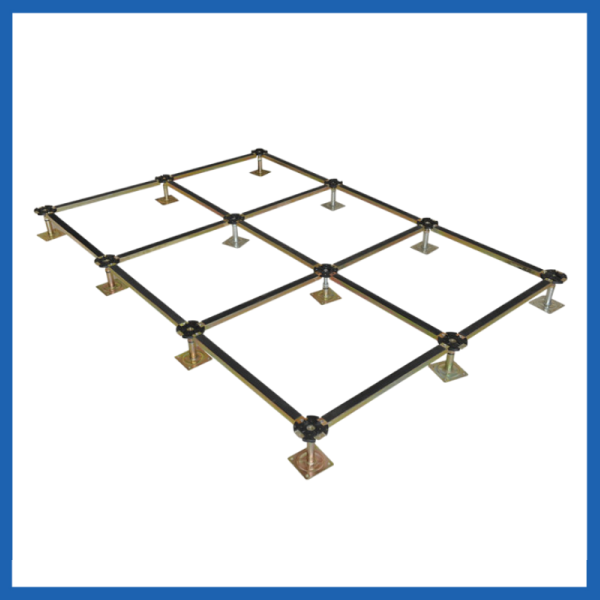

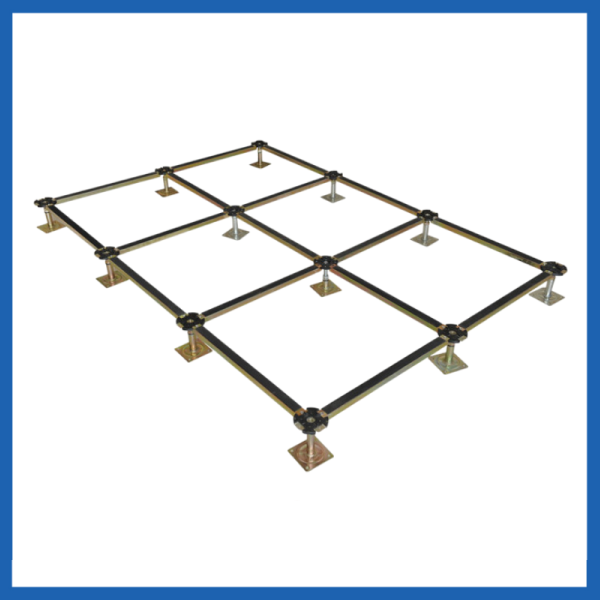

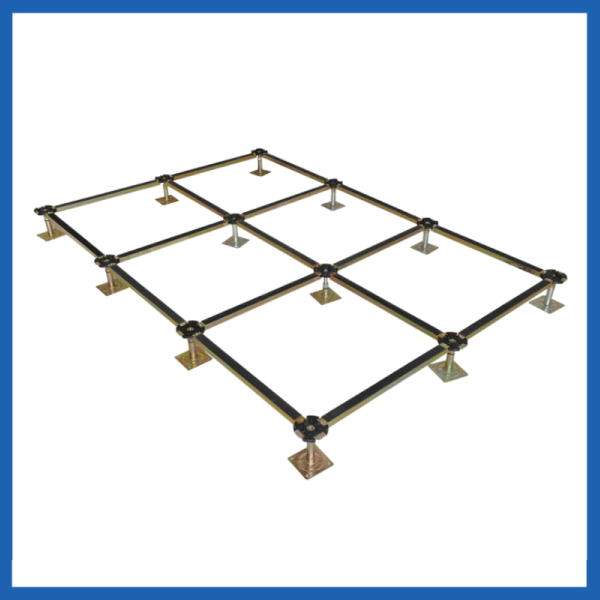

Stands: They are usually divided into standard, reinforced and super-strong stands. In addition, there are two special purpose brackets: slope bracket and side-closing bracket.

Standard bracket: composed of upper bracket, screw, locking nut, support tube and lower bracket, the support tube is generally 22 × 22mm square tube, Φ 22mm round tube, surface galvanized, with good rust and corrosion resistance.

Reinforced bracket: It has better load-carrying performance than standard brackets. The diameter of the supporting pipe is usually Φ 25mm, Φ 28mm, Φ 32mm.

Super bracket: Mainly used in places where high requirements for load-carrying performance and overhead height are required. The diameter of the supporting pipe is Φ 38mm, Φ 45mm, Φ 73mm etc.

Slope bracket: Mainly used for making slopes.

Side-closing bracket: Mainly used for edge treatment of floors

Other ancillary accessories are diagonal brackets, horizontal pull bars and hoops as ancillary connectors of the brackets. Usually they are combined with extra-high and extra-strong brackets to enhance the stability of the floor installation structure. Screws, suction cups, wiring boxes, etc.

The types of anti-static floors are: all-steel anti-static floor, composite ceramic anti-static floor, calcium silicate anti-static floor, calcium sulfate anti-static floor, aluminum alloy anti-static floor, carbon steel anti-static floor, PVC anti-static floor, anti-static ventilation floor, etc. According to the different use environment, select the corresponding brackets.